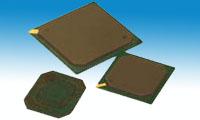

In semiconductor micro-chip packaging, microwave plasma cleaning and activation is used in applications of adhesion promotion of encapsulant mold compounds. This includes “glob top” and “flip chip underfill” processes. The highly reactive microwave plasma uses the chemical power of oxygen radicals to modify various substrate surfaces: solder mask materials, die passivation layers, bond pads as well as leadframe surfaces. Mold delamination problems are thus eliminated, and by using PVA TePla’s microwave plasma there is no risk of ESD or other potentially harmful side effects