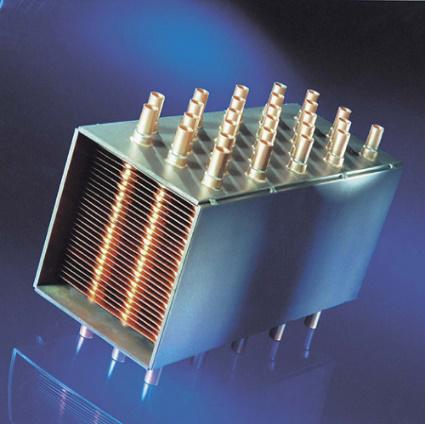

A Vacuum brazing furnace produces stronger and longer lasting joints that are leak tight, have minimal distortion while maintaining a clean bright surface. Typical alloys used in our vacuum brazing furnaces are copper and copper alloys, nickel alloys, silver alloys and gold and other precious metals. Our multi-chamber brazing furnace is ideally suited for the economic brazing of mass parts.

The multi-chamber vacuum brazing furnace ABI is ideally suited for the economic brazing of mass parts. Originally this system has been developed for the brazing of metal-ceramic over voltage arrestors (Arrestor Brazing In-Line). Palettes of approximately 250x250mm loaded with parts for brazing are automatically charged into the first furnace chamber and there evacuated and pre-heated before being transported into the brazing chamber permanently conditioned for the process. When the brazing cycle has been completed rapid cooling takes place before locking out.